|

|

|

|

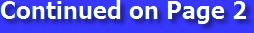

It all started with “Ugly Green Gator, the

Gladiator”. Yep, that’s what all my

“buddies” called my 1974 J-10, that was

obviously the factory green, faded and

rusted. It came with a 258 six cylinder,

T-18 4-speed manual, Dana 20 transfer

case, and some obnoxious clearance lights

on the roof (which we promptly removed).

I had bought it with anticipation of

someday building a really cool J-10 like

the pre-runners I’d seen hanging around

the off-road races, back in the early

1980’s. It went through several

changes, with the ugly green paint,

including suspension up-grades, bumper

changes and tires/wheels.

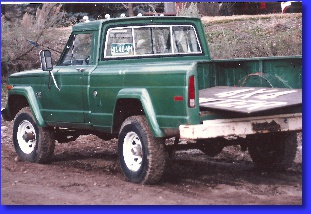

Finally, it was time to do some drive

train up-grades. I was in the process of

parting-out a 76 Jeep CJ-7 that had a

AMC 304 V-8, TH400 automatic

transmission and a Quadra-Track

transfer case, and transplanted them

into Gator’s chassis. After the bigger

engine, I had a friend paint it white and

stripe it. It lasted this way several

years.

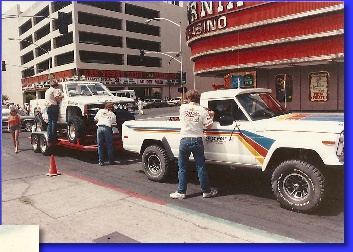

Then I decided it needed even more

power, and we built a AMC 401 V-8,

with some up-grades like a mild cam,

390 AMX heads that except 6 to

1-ratio, roller rockers arms, better

oiling system, Thorley Tri-Y headers

and a carter 625 4-bbl carb. The new

401 ran good enough to surprise the

average Camaro owner!

After a few years of abuse, serving as a tow rig, pre-runner, shop truck, and daily driver, it

was time for a major body-off, frame-up rebuild. I acquired a 1980 cab (no brow), and

sandblasted the entire thing. Then did some major floor patching and built the internal cage.

Custom sheetmetal plates were built with hundreds of dimpled holes, for strength and the

cool look. They attached the DOM tubing to the cab interior. Each corner of the cage legs

extended through the floor and would act as the new cab mounts to the frame (through

polyurethane bushings). The entire cage was welded to the sheetmetal interior, forming one

very solid platform.

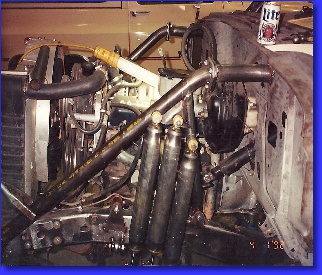

The entire chassis would also

benefit from the cage. Since the

cab was now attached directly to

the chassis, the rear kickers also

attached to the frame in three

places each, and at the upper

cab/rear window area. You can

see how this forms a “bridge”

over the frame and adds

tremendous strength to the

entire chassis. It also acts as a

great attachment point for

suspension components (shocks)

and other essentials.

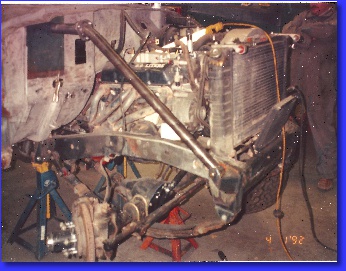

On the firewall side, I extended

tubing through the sheetmetal (with

careful considerations for

components like the heater, A/C, and

fuse box). These extensions have

bolt/flanges to allow easy removal of

underhood tubing. The bolted on

tubes go directly to the frame and

also connect in three places each.

The cage structure now bridges the

chassis and is connected in 16 places

with poly-bushings.

I’ve always been a fan of the Jeep J-10

step side trucks, so I decided to

convert the style-side bed, to a

“glass-fender” step side. I found some

brand new fenders (long story), but

beds were no longer around (very

rare). So I built my own bed from

square tubing and sheetmetal.

I decided to raise it about 4” above the

stock step-side bed to make the truck look

taller, without adding height. This allowed

me to raise the step-side fenders up 4”

from stock. Plus this gave me more

clearance to fit the 35” tires under the

fenders.

Story and photos by Chris Overacker

Edited by Mark Smith